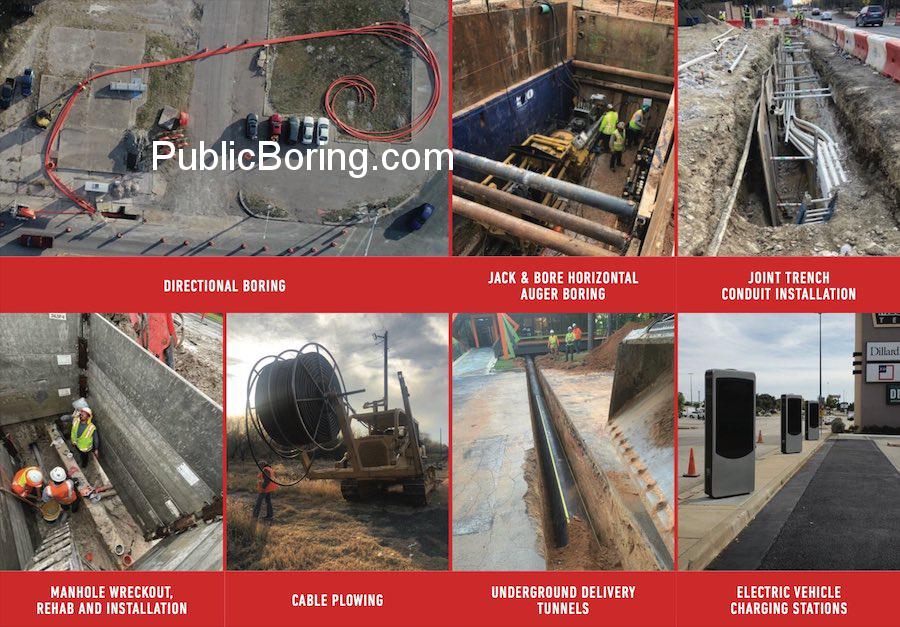

Jack and Bore Pipe Installation: A Comprehensive Overview

Jack and Bore, a renowned trenchless method, is primarily employed for the installation of pipes or casings beneath obstacles such as roadways, highways, railroads, and other structures. This method prioritizes minimal surface disruption while providing an efficient means of installing underground conduits. Here’s a detailed breakdown of the steps and services tied to Jack and Bore Pipe Installation:

- Initial Planning and Site Evaluation:

- Construction Site Development: A comprehensive assessment of the construction site is carried out, determining boreable regions and understanding the existing underground architecture.

- Engagement of Professional Entities: Reputable companies and corporations, spanning from LLCs to Co-ops, assemble a specialized team of pros and experts to give insights on the ideal jack and bore strategies for the project at hand.

- Preparing the Site:

-

- Excavation: Initial work begins with the excavation of launch and receiving pits. In regions with existing utilities, hand digging or hand trenching techniques are applied to prevent accidental damages.

- Manhole Wreckout and Setup: Before the actual boring process, any existing manhole is meticulously rehabilitated, ensuring optimal installation conditions.

- Boring and Pipe Installation Process:

-

- Auger Boring: An auger, specialized for the best performance, drills from the jacking pit towards the receiving pit. This becomes particularly effective in terrains like hard rock.

- Continuous Bore & Pipe Installation: As the bore progresses, the pipe or casing (often steel) is systematically jacked into place, ensuring a stable, horizontal conduit below the obstruction.

- Utility Integration:

-

- Conduit and Ductbank Work: Within the installed casing, conduits are positioned to protect utilities such as electric cables, fiber optics (like FTTB, FTTH, or FTTCS), or even provisions for electric vehicle charging stations. For more extensive utility installations, a ductbank might be structured.

- Collaboration and Regulatory Adherence:

-

- Interactions with Authorities: Vital permissions are sourced from local or federal government, especially if operations are proximate to interstates, military zones, or other critical infrastructures.

- Subcontractor Involvement: Some segments of the project may necessitate subcontractors’ expertise, ensuring that every phase is executed with the utmost precision and skill.

- Project Completion and Post-Installation Work:

-

- Landscape Rehabilitation: Following the jack and bore activity, the impacted landscape undergoes restoration, reverting it to its original state or even enhancing it.

- Safety Inspections: The newly installed utilities and infrastructure are subjected to rigorous safety checks and inspections, verifying their operational integrity.

- Emergency Preparedness & Maintenance:

-

- Swift Response Protocols: Teams remain on standby for emergencies, ensuring that any unexpected disruptions are addressed ASAP.

- Routine Maintenance: Regular checks and maintenance tasks are conducted, ensuring the installed utilities’ longevity and functionality.

In essence, Jack and Bore Pipe Installation stands out as a method combining efficiency, safety, and environmental consideration. Whether it’s used for enhancing smart cities, laying conduits for sustainable energy like solar farms, or other underground construction projects, it’s a method that consistently delivers results.