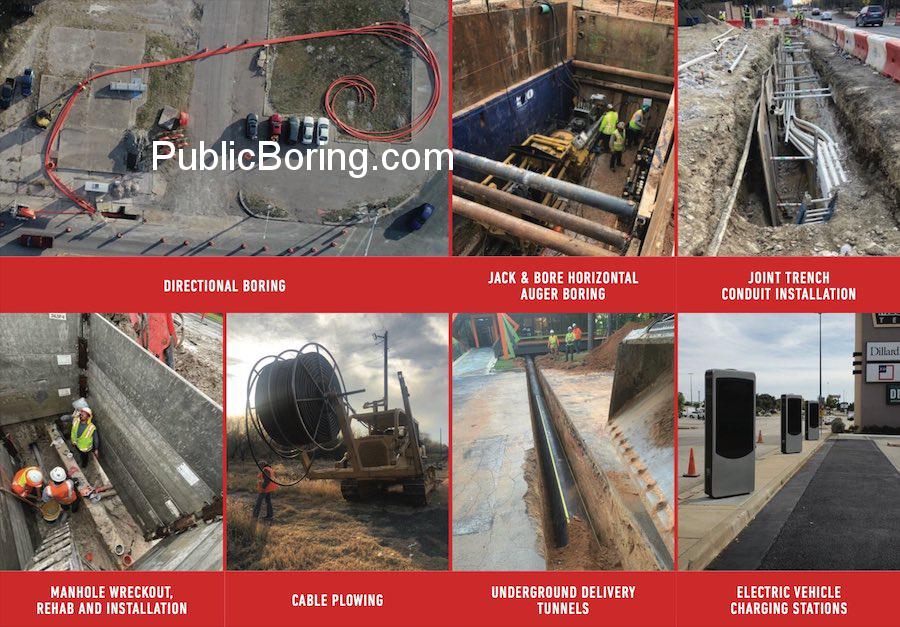

Directional Boring: An In-Depth Guide to the Process and Services

Directional boring, also known as horizontal directional drilling (HDD), is a trenchless method used to install underground utilities, including conduits, pipes, and cables. It’s preferred for its minimal surface disruption, especially in developed or sensitive areas. Here’s a comprehensive breakdown of the process and services associated with directional boring:

- Planning and Initial Assessment:

- Engagement of Experts: Specialized companies or corporations are consulted to assess the feasibility and requirements of the project, offering their expertise in directional boring.

- Site Development: A detailed survey of the construction site is conducted, considering soil conditions, existing underground utilities, and the proposed path of the bore.

- Equipment Selection:

-

- Best Boring Equipment: Depending on the complexity and size of the project, the best-suited boring equipment is chosen. For tougher terrains, hard rock boring machines may be necessary.

- ASAP Auger & Other Tools: Depending on site conditions, other tools, such as the ASAP Auger, may be employed for specific segments or for preparatory tasks.

- Directional Boring Process:

-

- Pilot Bore: A small-diameter pilot hole is drilled along a predetermined path using a directional bore machine.

- Reaming: To achieve the desired size for the utility installation, the pilot hole is enlarged in a process called reaming.

- Utility Pullback: The desired utility, whether electrical, fiber, conduit, or sewer, is then pulled back through the reamed hole, establishing the underground installation.

- Utility and Infrastructure Services:

-

- Fiber Boring: Special techniques are employed when boring specifically for telecommunications, facilitating the installation of services like FTTB, FTTH, FTTCS, and FTTT.

- Electrical & EV Charging Stations: Directional boring can be used to establish underground electrical connections, including infrastructure for electric vehicle charging stations.

- Conduit Installation: During the utility pullback phase, conduits might be installed to house and protect various utilities.

- Specialized Boring Techniques:

-

- Slick Bores: This is used for smoother installations, especially for delicate utilities.

- Jack and Bore: A method used typically for crossing beneath railways, roads, or other obstacles, where a pit is dug on either side, and boring is done from one pit to the other.

- Collaboration and Partnerships:

-

- Working with Government and Military: On public or specialized projects, partnerships with government entities or military organizations might be established.

- Co-op and Local Engagements: Local co-ops or LLCs might be involved in community-based or smaller-scale projects.

- Subcontracting: Bigger projects might involve various expertise areas, and thus subcontractors may be brought in for specific tasks.

- Post-Boring Activities:

-

- Landscape Restoration: After the boring process, efforts are made to restore the surface area, ensuring the landscape returns to its original state or better.

- Manhole Services: Where access points or junctions are required, services related to manhole wreckout, rehabilitation, and placement might be conducted.

- Emergencies and Contingencies:

-

- Rescue & Repair: In the face of unexpected challenges or damages, companies come equipped with emergency response mechanisms to ensure the safety and continuation of the project.

- Advancements and Future Projects:

-

- Smart Cities & Renewable Energy: As urban centers evolve and the demand for renewable energy sources like wind and solar farms increases, directional boring is essential to establish the foundational infrastructure with minimal disruption.

Directional boring serves as a cornerstone for underground construction in modern infrastructure projects. Its ability to navigate around obstacles, reduce surface damage, and provide swift installations makes it indispensable in the evolving urban landscape.