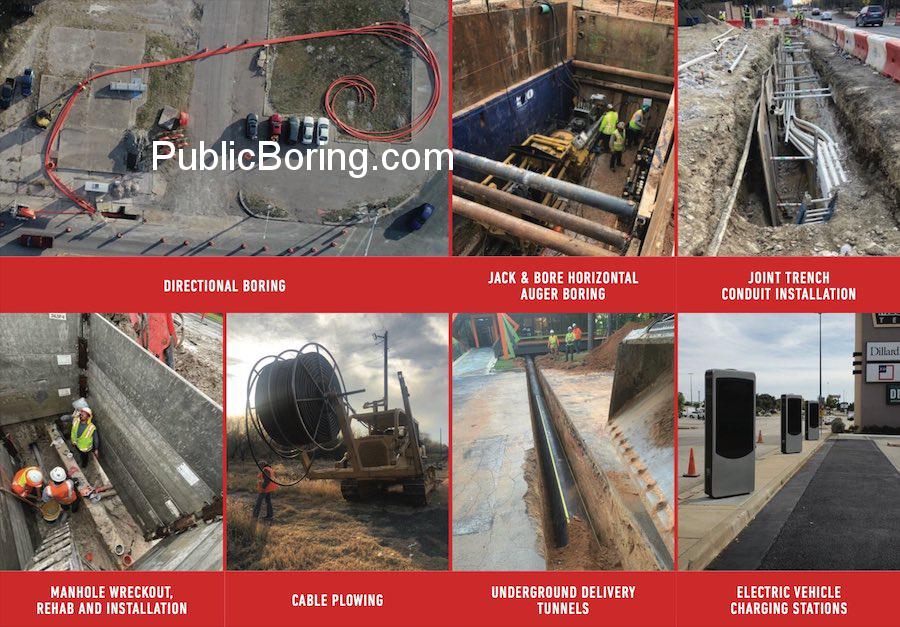

HDD Drilling: A Comprehensive Overview of Services and Processes

Horizontal Directional Drilling (HDD) is a trenchless method used primarily for the installation of underground utilities such as water lines, gas lines, and telecommunications cables. It minimizes environmental impact and is often chosen in scenarios where traditional excavation is impractical or prohibited. Here’s a breakdown of the steps involved and services provided in HDD drilling using the given terms:

- Initial Planning and Survey:

- Consultation with Experts: Corporations or specialized HDD companies offer expertise in assessing the feasibility and challenges of a particular project.

- Site Development: Before the commencement of any drilling, the construction site undergoes detailed development, considering geographical and infrastructural constraints.

- Drilling Preparation:

-

- Excavation: While HDD is a trenchless method, excavation is still needed at the entry and exit points for the drill.

- Selection of Appropriate Drilling Method: Depending on the geology of the area, the best-suited drilling method is chosen. Hard rock terrains might require specialized drilling heads or techniques.

- Setting Up of Equipment: The necessary machinery, including the drill rig, is set up. In cases where large-scale utilities are being laid, even bigger equipment from major manufacturers might be used.

- Drilling Process:

-

- Pilot Bore: The initial bore is created, following the predetermined path. This is a crucial phase, ensuring that the bore does not deviate from its intended trajectory.

- Reaming: Once the pilot bore is established, it is enlarged to the required size to accommodate the utility. This may be done in multiple passes, especially in challenging terrains or for larger installations.

- Pullback: The utility, be it a conduit, cable, or pipeline, is then attached to the drilling head and pulled back through the bore, effectively installing it underground.

- Utility Installation:

-

- Conduit and Cable Plowing: In certain scenarios, additional utilities might be laid using methods like cable plowing.

- Blowing Fiber and Fiber Boring: Telecommunication utilities, especially those for fiber optics (FTTH, FTTB, FTTCS, and FTTT), are often installed using methods like blowing fiber.

- Ductbank Installation: In urban areas or places with dense underground infrastructure, ductbanks are installed to systematically house and protect multiple utilities.

- Collaborations and Stakeholder Engagement:

-

- Local and Government Engagement: Collaborations might be established with local LLCs, co-ops, or government entities, especially for projects near highways, railroads, or military installations.

- Subcontractor Engagement: For projects that require specialized skills or are expansive in scale, subcontractors might be engaged to expedite the process.

- Post-Installation:

-

- Landscape Restoration: Upon completion, the site is rehabilitated to ensure minimal environmental disruption.

- Inspection and Testing: The installed utility undergoes rigorous testing to ensure it meets the required standards and is ready for operation.

- Maintenance and Emergency Services:

-

- Routine Checks and Maintenance: Periodic inspections ensure the utility’s smooth functioning.

- Emergency Response: In cases of unexpected disruptions or issues, emergency teams are on standby for immediate rescue and rectification operations.

In summary, HDD drilling is a state-of-the-art solution to modern infrastructure challenges, providing an efficient way to install utilities with reduced environmental impact. With advancements in technology and growing demand, HDD companies continually refine their techniques to cater to diverse project requirements.