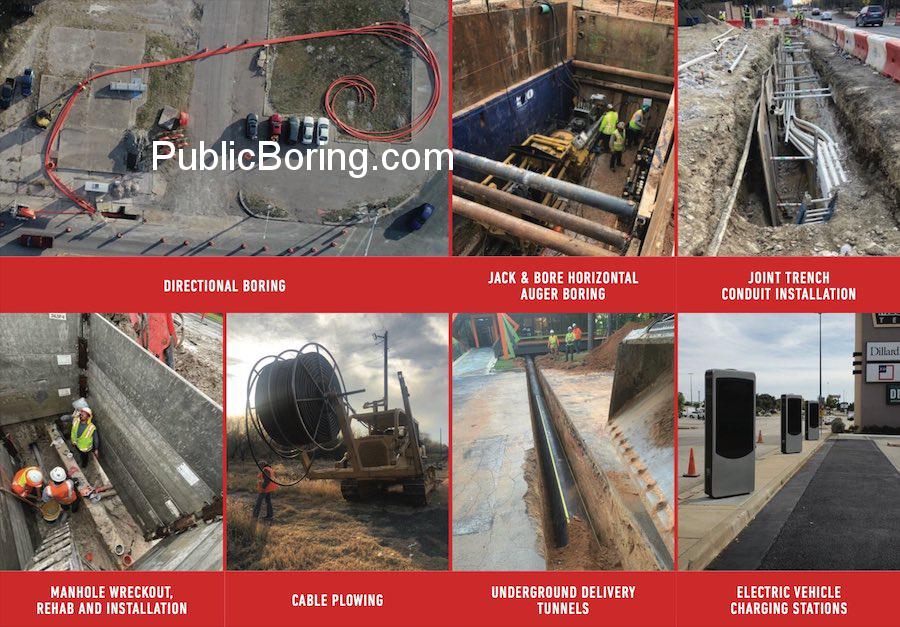

Horizontal Auger Boring: A Comprehensive Overview of Services and Processes

Horizontal Auger Boring (HAB) is a trenchless technology employed to install utilities beneath obstacles such as roadways, railways, and bodies of water. It is commonly used to facilitate the underground installation of infrastructure components, including conduits, sewers, and pipelines. Here’s an intricate description of the processes and services involved in Horizontal Auger Boring using the provided terms:

- Planning and Consultation:

- Site Survey and Development: Before actual construction, thorough construction site development and evaluation are essential to ascertain the subsurface conditions and the presence of any boreable obstacles.

- Expert Involvement: Pro companies and experts, often part of renowned corporations or LLCs, provide insights on the project’s feasibility and methodologies.

- Setup and Excavation:

-

- Entry and Exit Pit Creation: Excavation processes are employed to create the necessary pits. The landscape is kept in consideration to ensure minimal environmental disruption.

- Selection of Equipment: Given the project’s scope and requirements, the best Horizontal Auger Boring machinery is selected. Special attention is given to the drill head, especially if hard rock terrains are expected.

- Horizontal Auger Boring Operation:

-

- Boring Process: Using an auger, boring is carried out from the entry to the exit pit. The auger facilitates the removal of the excavated material.

- Conduit Installation: As the auger advances, conduits – which can house utilities like electrical cables, fiber, or sewer lines – are simultaneously installed in the borehole.

- Utility Installation:

-

- Utility Pulling: Post-boring, utilities like electrical cables, fiber optics for FTTH, FTTB, FTTCS, or FTTT are pulled through the conduits.

- Ductbank Construction: In urban environments or for projects requiring multiple utilities to run in proximity, ductbanks are constructed. This centralized infrastructure simplifies installation and future maintenance.

- Collaborations and Permissions:

-

- Government, Military, and Local Permissions: Especially crucial when the project is near highways, interstates, railroads, or military bases. Engaging with local, military, and government entities is essential to ensure a smooth process.

- Engaging Subcontractors: Subcontractors with niche expertise might be roped in for specific tasks, ensuring optimal project execution.

- Post-Boring Activities:

-

- Landscape Rehabilitation: After the Horizontal Auger Boring process, the disturbed landscape is restored.

- Inspection and Testing: All installed utilities undergo rigorous testing to ensure they’re operational and safe.

- Emergency and Maintenance Services:

-

- Emergency Measures: Pro teams are always on standby. In the case of any unexpected disruptions, these experts ensure swift rescue and remediation.

- Routine Maintenance: Periodic checks and maintenance routines are executed to guarantee the longevity and efficiency of the installed utilities.

In conclusion, Horizontal Auger Boring is an intricate process that requires meticulous planning, specialized equipment, and expert execution. Whether the project aims to bolster smart cities, solar farms, or more localized infrastructural needs, HAB stands as a testament to the advances in trenchless technology, offering efficient and minimally disruptive solutions for utility installations.