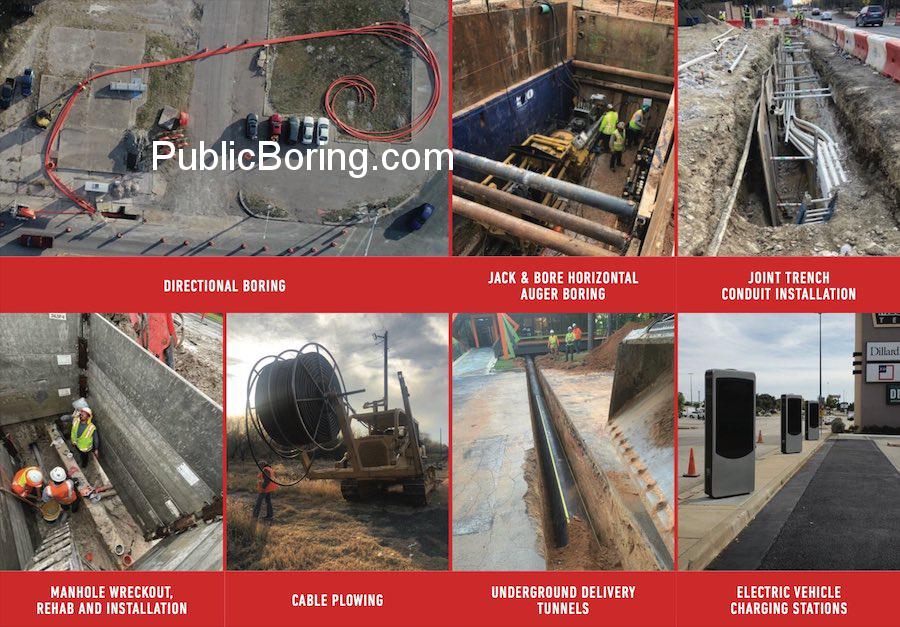

Horizontal Boring: A Comprehensive Overview of Services and Processes

Horizontal Boring, often synonymous with Horizontal Directional Drilling (HDD), is a trenchless method employed to install pipelines, conduits, and cables underground without significant ground disruption. It’s a sought-after technology for municipal, commercial, and residential infrastructure development. Here’s an intricate description of the processes and services involved in Horizontal Boring using the provided terms:

- Planning and Consultation:

- Construction Site Development: An initial assessment involving construction site development is crucial. Experts identify boreable terrains, obstacles, and potential environmental and infrastructural challenges.

- Engaging Experts: Leading companies, whether they’re corporations, LLCs, or other business entities, engage experts to provide insights into the feasibility, approach, and methodologies suitable for the project.

- Preliminary Work:

-

- Excavation: Before the actual boring, excavation may be necessary, especially for the creation of entry and exit pits. Hand digging or hand trenching can be used for more delicate areas where utilities or other obstructions are near.

- Joint Trenching: In situations where multiple utilities need to be installed parallelly, joint trenching is employed to optimize the process.

- Horizontal Boring Operation:

-

- Boring Under Obstacles: This technique is pivotal when the project involves bypassing obstacles such as highways, railroads, or rivers. The boring process ensures minimal disruption to these structures and the surrounding environment.

- Hard Rock Challenges: When encountering hard rock terrains, specialized boring equipment and techniques are used to ensure efficient penetration and progress.

- Utility and Conduit Installation:

-

- Conduit and Ductbank Installation: After the bore is established, conduits – which can house electrical cables, fiber optics, or other utilities – are installed. In densely populated or complex utility areas, ductbank installation becomes an organized solution to house multiple conduits.

- Pulling Utilities: Once conduits are in place, utilities such as fiber for FTTH, FTTB, FTTCS, electrical cables for EV charger stations, or OSP requirements are pulled through.

- Collaboration and Permissions:

-

- Engaging with Authorities: Necessary permissions from local, government, and possibly military entities are essential, especially for projects near or through public infrastructures like roads, interstates, or military zones.

- Collaboration with Subcontractors: Often, niche tasks within the project are outsourced to subcontractors, ensuring every aspect of the project is handled by specialists in that domain.

- Post-Boring Activities:

-

- Landscape Rehabilitation: Post the boring process, it’s imperative to rehabilitate the disturbed landscape, restoring it to its original or an improved state.

- Inspection and Testing: All installed utilities undergo rigorous testing to ensure functionality and safety. This might include fiber boring tests for optical fibers or electrical tests for cables.

- Maintenance and Emergency Services:

-

- Emergency Protocols: Pro teams and experts are available ASAP in emergencies. Swift rescue and problem-solving measures are employed if any disruptions or issues arise during or post the project.

- Routine Checks: Maintenance services and regular inspections ensure longevity and optimal performance of the installed utilities and infrastructures.

In summary, Horizontal Boring is an advanced, minimally invasive method ensuring efficient underground utility installations. Whether the objective is to advance smart cities, install utilities for solar or wind farms, or improve localized infrastructures, Horizontal Boring stands at the forefront, combining technology and expertise for enhanced urban and rural development.