Horizontal Directional Drilling (HDD): A Comprehensive Guide on Processes and Services

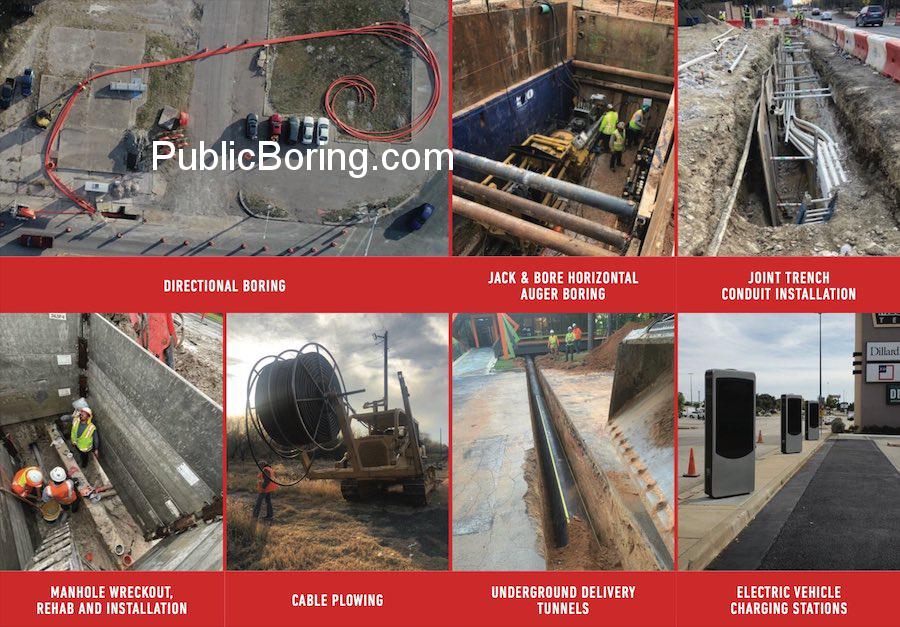

Horizontal Directional Drilling (HDD), also known as directional boring, is a trenchless construction method used to install underground infrastructure like pipelines, conduits, and cables without the need for open trenches. Leveraging this technology can dramatically reduce environmental impact and save costs. Here’s an in-depth look into the processes and services involved in HDD:

- Initial Assessment and Planning:

- Construction Site Development: Experts begin with a detailed assessment of the construction site to understand the terrain, existing underground utilities, and potential challenges. They determine boreable areas and estimate the trajectory of the bore.

- Collaboration with Professionals: Renowned companies or corporations, be it a Co-op, LLC, or other business entities, involve pro teams and experts to provide insights on the most efficient HDD techniques for the project.

- Site Preparation:

-

- Excavation: Although HDD minimizes excavation, establishing entry and exit pits is essential. For sites with existing utilities or sensitive structures, hand digging or hand trenching is preferred to ensure minimal disturbance.

- Joint Trenching: If there’s a need to install multiple utilities side-by-side, joint trenching might be employed. This approach streamlines the installation process.

- The Drilling Process:

-

- Pilot Hole Drilling: The first step involves creating a pilot hole using an auger or similar tools. This is a guided process that follows the planned trajectory, ensuring the bore bypasses obstacles like highways, railroads, or hard rock formations.

- Reaming: Once the pilot hole is established, it’s enlarged or reamed to accommodate the installation of larger infrastructure like conduits or pipelines.

- Utility Installation:

-

- Pulling: The desired infrastructure, whether electrical cables, fiber for FTTB, FTTH, FTTCS, or other utilities, is pulled back through the enlarged borehole. Conduits, which can protect and house these utilities, are commonly used.

- Ductbank Work: In areas with multiple utilities or complex infrastructural needs, a ductbank – a structured grouping of conduits – can be installed. This provides an organized approach to housing multiple utilities.

- Collaborations and Regulatory Approvals:

-

- Engaging with Authorities: Necessary approvals from government entities or local municipalities are sought, especially when the drilling is near public infrastructure, military zones, or protected areas.

- Working with Subcontractors: Specialized tasks may be outsourced to subcontractors to ensure the highest level of expertise for each project component.

- Post-Installation Procedures:

-

- Landscape Restoration: After the HDD process, the landscape is restored to ensure minimal environmental impact and aesthetic consistency.

- Testing & Inspection: Every installation is rigorously tested, be it fiber boring tests for optical lines or electrical tests for power lines, ensuring operational readiness and safety.

- Emergency and Maintenance Services:

-

- Rapid Response: In case of unexpected challenges or disruptions, emergency teams are on standby to act ASAP. Their goal is to minimize downtime and rectify issues swiftly.

- Maintenance: Regular maintenance checks and services ensure the long-term functionality and safety of the installed utilities.

In essence, Horizontal Directional Drilling is an amalgamation of advanced techniques, professional expertise, and strategic planning, making it an invaluable method in modern infrastructure development. Whether the goal is to enhance smart city networks, facilitate renewable energy sources like solar or wind farms, or provide essential local utilities, HDD leads the way in sustainable and efficient underground construction.