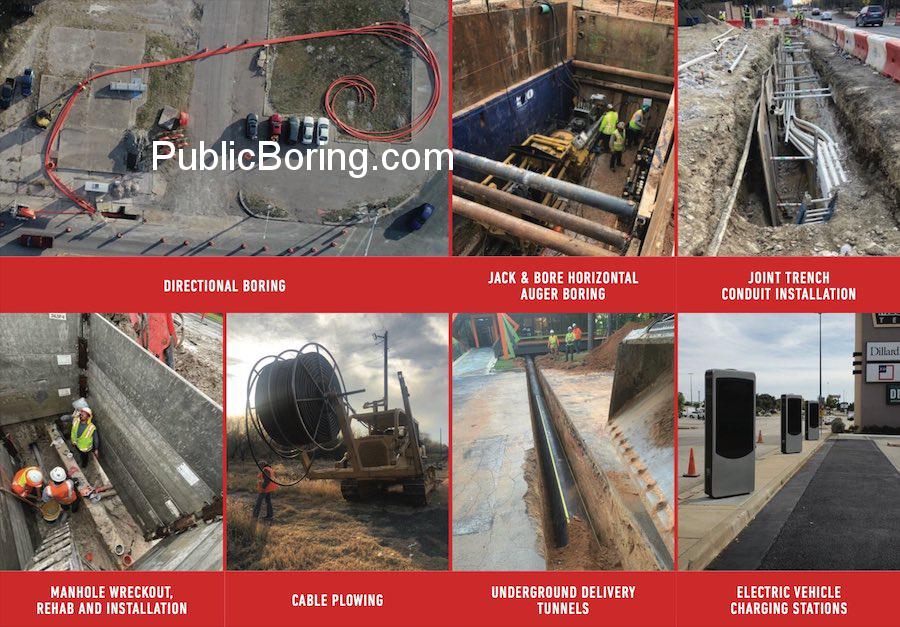

Jack and Bore: A Comprehensive Guide on Processes and Services

Jack and bore, also known as auger boring, is a trenchless method utilized primarily for the installation of steel pipes or casings under roadways, railroads, finished landscapes, and other obstructions. It’s a preferred choice in scenarios where surface disruption is undesirable. Below is a thorough outline of the steps and services associated with a jack and bore job:

- Planning and Assessment:

- Construction Site Development: Experts begin by evaluating the construction site to identify potential challenges, ascertain boreable areas, and understand existing underground utilities.

- Collaboration with Professional Entities: Leading companies, whether they’re LLCs, Corps, or Co-ops, bring together a team of pros and experts to offer insights on the optimal jack and bore techniques for the specific project.

- Site Preparation:

-

- Excavation: Jack and bore requires setting up launch and receiving pits. In areas with pre-existing utilities, hand digging or hand trenching might be employed to avoid damages.

- Manhole Wreckout and Preparation: Prior to the boring process, any existing manhole is rehabilitated, and necessary wreckouts are performed to ensure smooth installation.

- Boring Process:

-

- Auger Boring: Using an auger, the bore is initiated from the jacking pit towards the receiving pit. This method is especially suitable for harder terrains like hard rock.

- Continuous Boring: As the auger progresses, the casing (usually made of steel) is jacked into place from the launch pit, ensuring stability of the bore.

- Utility Installation:

-

- Conduit Placement: Within the installed casing, conduits are placed to house and protect utilities such as electrical cables, fiber optics (FTTB, FTTH, FTTCS), etc.

- Ductbank Work: If the project involves multiple utilities, a ductbank might be constructed within the casing, ensuring organized and secure housing for the utilities.

- Collaboration & Regulatory Adherence:

-

- Engagement with Authorities: Necessary permissions from local or federal government entities are obtained, especially when operations are near highways, interstates, railroads, military areas, or other critical infrastructure.

- Partnership with Subcontractors: For specialized segments of the project, subcontractors might be engaged, guaranteeing that each phase is handled with utmost expertise.

- Completion and Restoration:

-

- Landscape Restoration: After the jack and bore operation, the affected landscape is rehabilitated to its original or better condition, ensuring minimal ecological and aesthetic disturbance.

- Inspection & Testing: The installed utilities and infrastructure are subjected to rigorous tests and inspections to ensure safety, functionality, and compliance with standards.

- Emergency & Maintenance Provisions:

-

- Prompt Response: Emergency teams are always on standby. Should there be unexpected challenges or disruptions, they’re ready to act ASAP, ensuring issues are swiftly resolved.

- Routine Checks: Maintenance teams conduct regular checks to ensure the longevity, safety, and functionality of the installed utilities.

In summary, jack and bore stands out as a strategic, efficient, and eco-friendly solution in the realm of underground construction, especially when it’s crucial to avoid surface disturbances. Its versatility makes it suitable for diverse projects, from enhancing smart city networks to laying down conduits for renewable energy sources like wind or solar farms.