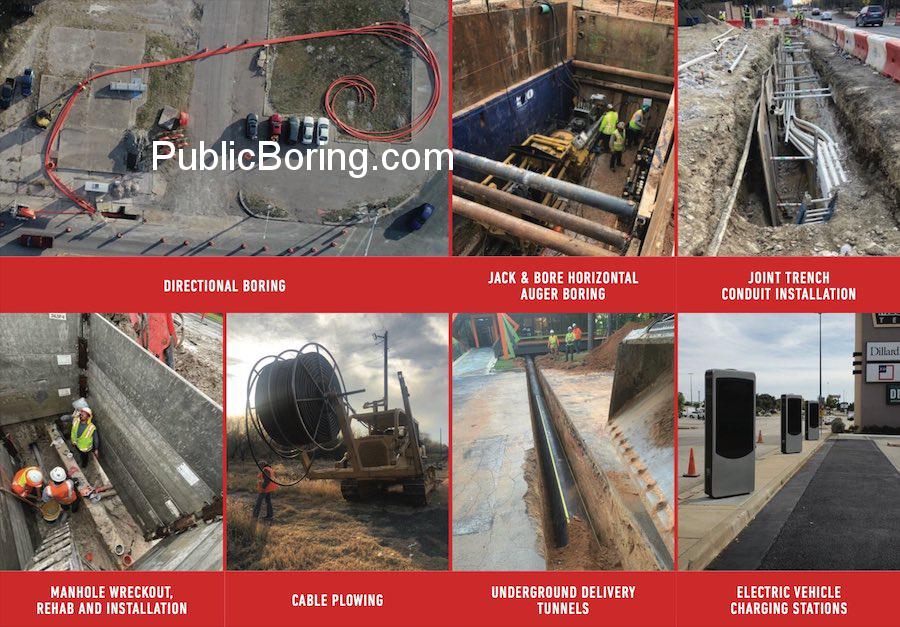

Joint Trench Utilities: An In-depth Overview

Joint Trench Utilities streamline the deployment of various infrastructural elements by combining them into a shared trench, thus maximizing efficiency and minimizing disruption. The process is multifaceted, involving extensive planning, collaboration, and a combination of traditional and cutting-edge techniques. Here’s a comprehensive examination of Joint Trench Utilities using the provided terms:

- Planning & Coordination:

- Construction Site Development: Before any excavation or installation, an exhaustive assessment of the construction site identifies boreable zones, ensuring optimal joint trench placement.

- Collaboration of Entities: Companies, co-ops, and corporations join forces, marshaling their collective expertise to chart the best approach for joint trench utility deployment.

- Excavation:

-

- Conventional & Trenchless Techniques: Depending on site conditions, conventional trenching methods or trenchless options like horizontal boring might be deployed.

- Auger & Excavation: Mechanical methods such as augers help excavate the trench, particularly in hard rock areas. In sensitive zones, hand digging and hand trenching might be employed to avoid collateral damage.

- Utility Deployment:

-

- Ductbank Installation: A primary element in joint trenches, the ductbank provides a structured environment for conduits, ensuring utility protection.

- Conduit Installation: Conduits house various utilities from electrical cables to fiber optics (encompassing FTTB, FTTH, FTTCS, etc.), even making provisions for electric vehicle charging stations.

- Special Utility Installations:

-

- Cable Plowing & Blowing Fiber: While cable plowing offers direct utility placement, blowing fiber provides a swift method to lay fiber optic cables within conduits.

- Small Cell & Smart Cities: Provisions for small cell installations facilitate the communication backbone necessary for modern smart cities.

- Regulatory & Collaboration Efforts:

-

- Government Liaison: Essential permits from government entities, especially when trenching near highways or interstates, are secured.

- Subcontractor Involvement: Subcontractors with specialized skill sets might be brought onboard, ensuring meticulous utility installation.

- Post-Deployment Procedures:

-

- Landscape Rehabilitation: Once utilities are installed and trenches filled, landscaping restores the site, often enhancing its previous state.

- Manhole Installation & Rehabilitation: Manholes, essential for underground utility access, are strategically placed or rehabilitated post-installation.

- Maintenance & Emergency Protocols:

-

- Emergency Protocols: Should emergencies arise, contingencies are set to address issues ASAP, minimizing disruptions.

- Inspections & Maintenance: Routine checks ensure the utilities’ longevity and functionality, with provisions for easy underground access when necessary.

In essence, Joint Trench Utilities symbolize an innovative approach to underground construction. By consolidating multiple utilities into one trench, they optimize costs, time, and labor, offering a comprehensive solution for modern infrastructure demands, from advanced fiber networks to electric vehicle charging. This approach guarantees a harmonized, effective, and efficient utility installation that serves the needs of both the present and the future