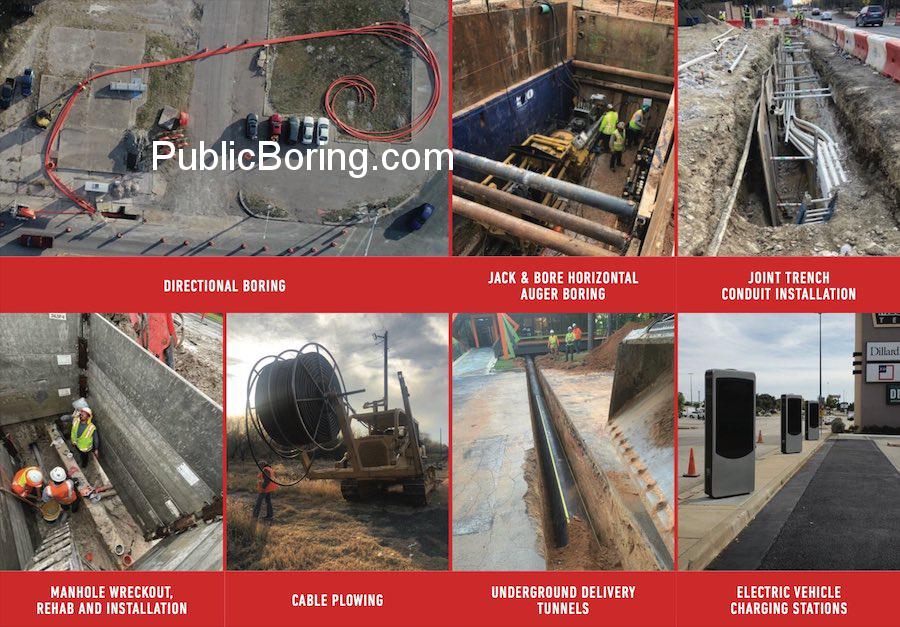

Pipe Boring: A Comprehensive Guide to the Process and Services

Pipe boring, an essential component of the trenchless technology sector, offers a less disruptive means to install underground utilities like water, gas, sewer, and telecommunications. By utilizing specialized equipment and techniques, pipe boring allows for precision installation with minimal surface disturbance. Utilizing the provided terms, here’s a detailed breakdown of the procedure and the services encompassed within pipe boring:

- Planning and Preliminary Work:

- Construction Site Development: Before commencing the boring process, professionals undertake a detailed evaluation of the site to determine boreable areas, ensuring the best location and approach for the project.

- Co-op and Corporation Collaboration: Often, different entities, whether they’re LLCs, companies, or larger corporations, collaborate to leverage combined expertise and resources.

- Initiating the Boring Process:

-

- Bore & Bores Assessment: Boring experts will ascertain the bore’s path, considering potential challenges, including hard rock layers or other underground structures.

- Auger and Boring Equipment: Depending on the project size and requirements, an auger might be employed alongside other boring machinery to drill through the ground.

- Utility and Infrastructure Integration:

-

- Cable Plowing and Blowing Fiber: For telecommunications or fiber optic installations, methods like cable plowing or blowing fiber are adopted post-boring to place cables within the conduit.

- Ductbank Installation and Work: In certain scenarios, especially in urban or smart cities infrastructure, a ductbank—a cluster of conduits—might be incorporated, facilitating the organized grouping of multiple utilities.

- Pipe and Conduit Installation:

-

- Conduits: These are the protective casings that house cables or smaller pipes. Post-boring, conduits are often pulled or placed into the bored path.

- Direct Installation: In some cases, the pipe or utility is installed directly during the boring process itself.

- Safety and Compliance:

-

- Government Regulations: Adherence to local and federal regulations, especially when working near highways, interstates, or military zones, is crucial.

- Emergency Protocols: Ensuring safe practices and having emergency rescue procedures in place is imperative for both the workforce and the surrounding community.

- Completion and Site Restoration:

-

- Landscape Restoration: Once the boring and pipe installation are complete, the surface is restored to its original state, minimizing environmental impact.

- Inspection and Quality Control: Post-installation checks, possibly involving OSP (Outside Plant) professionals, ensure that the installed utility conforms to standards and operates efficiently.

- Additional Services and Considerations:

-

- Electric Vehicle Charging Stations & Solar/Wind Farms: As sustainable energy gains traction, pipe boring can also facilitate the underground components of EV chargers, solar farms, or wind farms.

- Manhole Installation & Rehabilitation: Some projects might require the placement of manholes along the conduit’s length for access and maintenance. Old or deteriorated manholes might also undergo rehabilitation as part of the broader project.

In conclusion, pipe boring is a sophisticated, environmentally considerate method to install underground utilities. It amalgamates the expertise of various professionals and the finesse of cutting-edge machinery to deliver services crucial to modern infrastructure. Whether you’re seeking local experts or industry leaders, understanding the intricate steps and services involved in pipe boring can help streamline projects and ensure high-quality outcomes.