Rock Sawing: A Comprehensive Guide to the Process and Services

Rock sawing is an intricate procedure adopted to cut through hard rock layers, particularly during the construction of utilities and infrastructure. This method ensures a precise, clean, and efficient approach, minimizing disruption and maximizing safety. Using the provided terms, here’s a comprehensive breakdown of the rock sawing process and the encompassing services:

- Initial Assessment and Planning:

- Construction Site Development: A thorough analysis of the intended rock sawing area is conducted to assess the site’s feasibility, ensuring optimal placement and approach.

- Bore and Bores Evaluation: Experts inspect the hardness and composition of the rock, deciding upon the best sawing strategy.

- Co-op and Corporation Involvement: Collaboration between various entities, from local LLCs to large corporations, ensures pooling of resources and expertise.

- Rock Sawing Procedure:

-

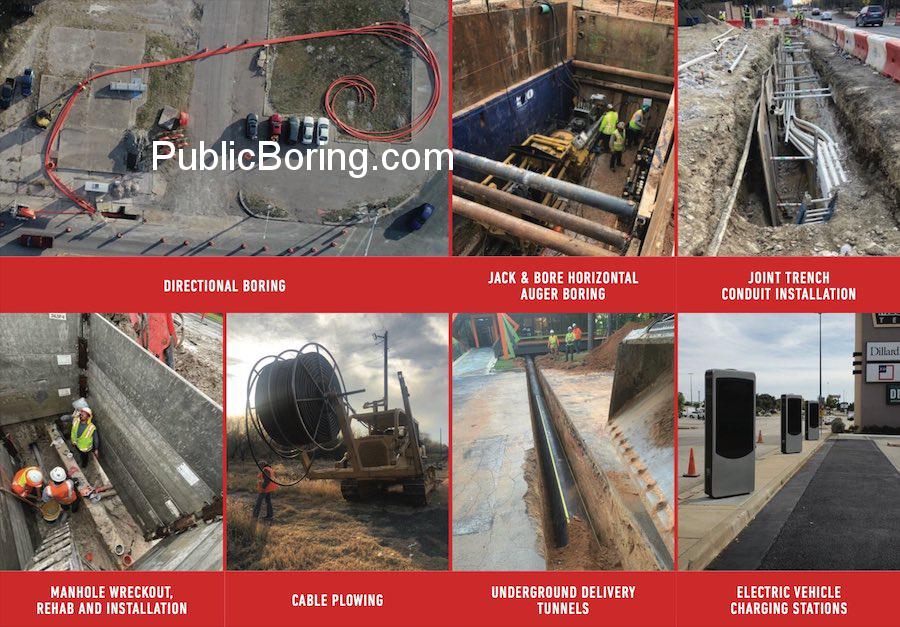

- Conventional and Horizontal Techniques: Depending on the specific project requirements and the rock’s orientation, either conventional (vertical) or horizontal sawing methods might be adopted.

- Hard Rock Challenges: Specialized equipment and techniques are deployed to navigate particularly hard rock formations.

- Trenching and Excavation: Post sawing, excavation or trenching may be required to remove rock debris and prepare the site for further development.

- Utility and Infrastructure Laying:

-

- Ductbank Work and Installation: Once the rock has been sawed and the site prepared, a ductbank, which houses multiple conduits, may be installed, especially for urban or smart cities infrastructure.

- Cable Plowing and Blowing Fiber: For telecommunications projects, following rock sawing, cables might be laid using methods like cable plowing or blowing fiber.

- Conduit Placement: Protective casings for utilities are installed in the sawed-out path.

- Safety and Regulatory Adherence:

-

- Government and Military Protocols: Especially crucial when working near highways, interstates, or military areas, rock sawing operations must comply with local and federal regulations.

- Emergency Rescue and Measures: With the inherent risks of working with hard rock, having emergency protocols in place is crucial for the safety of the workforce and the surrounding area.

- Post-Sawing Activities and Restoration:

-

- Landscape Rehabilitation: The affected surface area is restored to minimize the environmental and aesthetic impact post rock sawing.

- Manhole Installation & Rehabilitation: In projects requiring access points post sawing, manholes might be placed, and any existing ones might be rehabilitated.

- Special Services and Considerations:

-

- Electric Vehicle Charging Stations & Renewable Energy Infrastructure: With the push towards sustainable energy, rock sawing might also aid in setting up underground components for EV chargers, solar farms, or wind farms.

- Outside Plant (OSP) Inspection: Post-sawing, OSP experts might be called upon to ensure that the utility installation meets industry standards.

- Subcontracting and Expert Consultation:

-

- Subcontractors and Expert Involvement: Sometimes, specialized tasks within the broader rock sawing project might be subcontracted to niche experts for optimal results.

In summary, rock sawing is a complex yet essential procedure in the realm of underground construction, enabling infrastructure development even in challenging terrains. By understanding the steps and services involved in rock sawing, stakeholders can ensure projects are executed efficiently, safely, and to the highest quality standards.