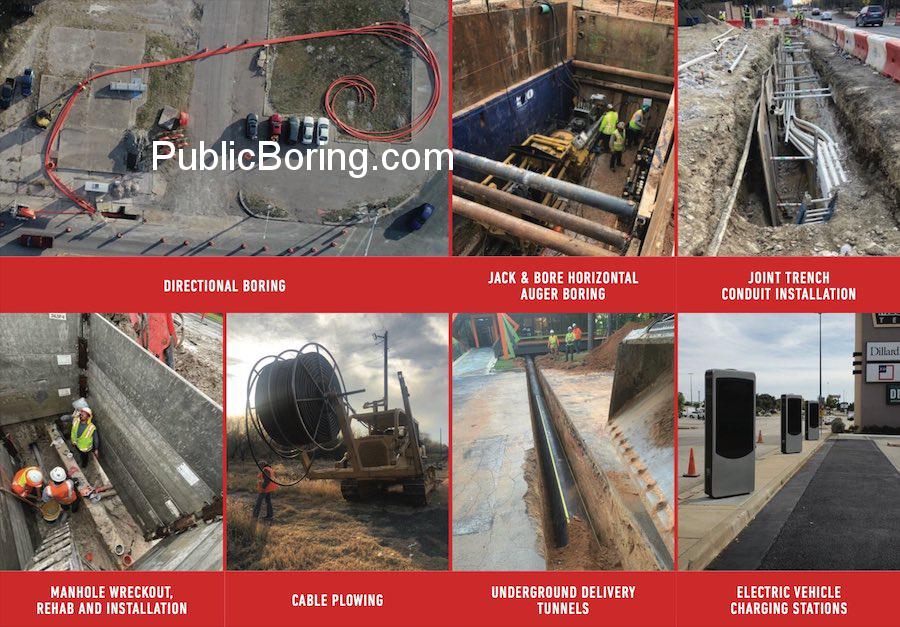

Trenchless Boring: Comprehensive Overview of Roles, Steps, and Services

Trenchless boring, a revolution in underground construction, facilitates the installation of infrastructure without the need for open trenches. This minimally invasive technique has gained traction due to its reduced environmental and logistical impact. Here’s a detailed breakdown of the services and steps involved in trenchless boring, integrating the provided terms:

- Initial Consultation and Planning:

- Engaging Experts: Local corporations, LLCs, or co-op entities seeking underground solutions often consult trenchless boring companies.

- Site Assessment: Before any work begins, experts evaluate the construction site, ensuring areas are boreable, especially considering challenges like hard rock.

- Government and Military Permissions: If the project is near sensitive areas such as highways, interstates, or military zones, necessary permissions are sought.

- Preparation for Boring:

-

- Horizontal Planning: Given that trenchless boring often involves horizontal drilling, meticulous planning ensures the desired depth and direction are achieved.

- Auger and Hand Digging: In some situations, minor digging or augering might be needed to facilitate the boring process or to create entry and exit points.

- Trenchless Boring Process:

-

- Conventional vs. Slick Bores: Depending on the ground conditions and project needs, either conventional bores or slick bores might be employed.

- Direct Boring: Using advanced machinery, a bore is created underground.

- Conduit and Ductbank Installation: As the bore is created, conduits or ductbanks can be introduced simultaneously, providing a protective casing for utilities.

- Fiber Boring: Post conduit installation, the system is ready for blowing fiber for telecom utilities like FTTH, FTTB, FTTCS, and FTTT.

- Post-Boring Activities:

-

- Manhole Installation and Rehabilitation: Manholes are strategically placed, ensuring maintenance access in the future.

- Landscape Restoration: The site is restored to its original state, minimizing environmental disruption.

- Utility Integration:

-

- Utility Pulling: After the bore and conduit installations, utilities, be it electrical cables, sewer lines, or others, are pulled through.

- Electric Vehicle Charging and Other Installations: Some projects might specifically target the infrastructure for EV charging stations, smart cities utilities, or small cell installations.

- Collaboration and Specialized Services:

-

- Working with Subcontractors: Trenchless boring companies often engage subcontractors for specialized tasks, ensuring every phase is managed by pros.

- Joint Trench Initiatives: In scenarios where multiple utilities are needed side by side, joint trench solutions might be integrated.

- Emergency and Contingencies:

-

- Emergency Response: Given the underground nature of the operations, a mechanism for rapid response in case of emergencies, such as utility breaches, is established.

- Rescue Operations: Should any complications arise during the boring process, expert rescue teams are always on standby.

- Maintenance and Future Upgrades:

-

- OSP (Outside Plant) Management: With the installed utilities being part of the outside plant, companies ensure their long-term management and maintenance.

- Upgrades and Extensions: The infrastructure laid through trenchless boring can be easily upgraded or extended in the future as needed.

In essence, trenchless boring stands as a testament to how advanced engineering can harmonize with environmental consciousness. Through expert planning, execution, and collaboration, it ensures seamless underground infrastructure development with minimal surface disruption.