Tunnel Boring: Comprehensive Overview of Roles, Steps, and Services

Tunnel boring is a method used for excavating and creating tunnels with minimal surface disruption. Typically, a tunnel boring machine (TBM) is employed for this process, ensuring accuracy, safety, and efficiency. Integrating the given terms, here’s a detailed look into tunnel boring:

- Initial Consultation and Assessment:

- Engagement with Experts: Local LLCs, corporations, and co-op entities contemplating underground projects approach specialized tunnel boring companies.

- Site Evaluation: Before initiating, experts assess the construction site, determining the boreability of the region and identifying challenges like hard rock.

- Project Planning:

-

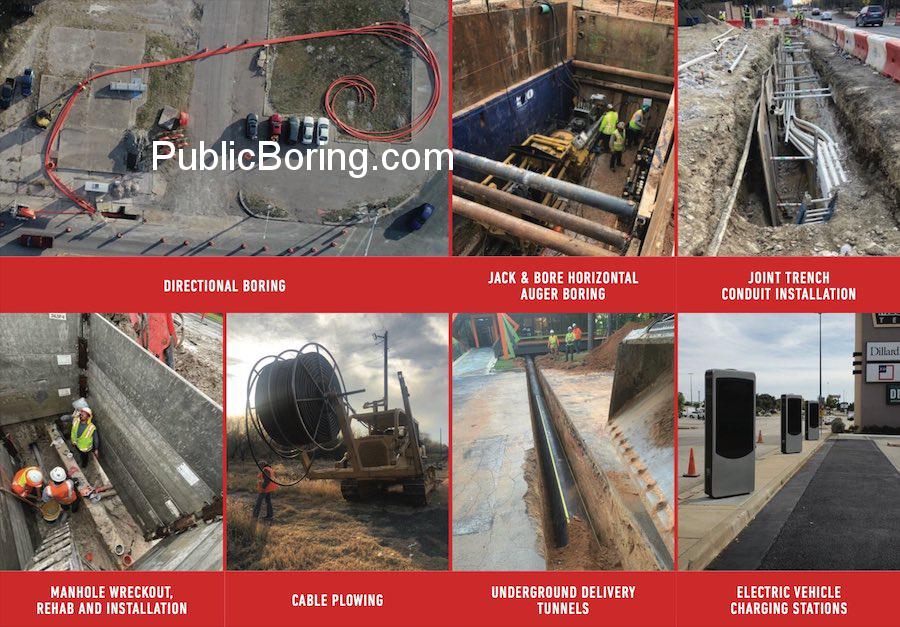

- Horizontal Analysis: As tunnel boring often pertains to horizontal drilling, planning ensures precise depth and direction.

- Government and Military Permissions: Necessary clearances are obtained, especially if the tunneling is near highways, interstates, or military zones.

- Tunnel Boring Execution:

-

- Machine Selection: Based on the ground conditions, the best-suited tunnel boring machine is chosen, whether for conventional bores or slick bores.

- TBM Launch: The massive TBM starts its excavation process, creating a bore for the tunnel.

- Conduit and Ductbank Work: Alongside the boring, conduits or ductbanks can be integrated, offering protective casing for subsequent utilities.

- Utility Integration: Utilities, whether electrical or fiber, are then incorporated within the created tunnel.

- Specialized Services & Installations:

-

- Fiber Boring: Post tunnel creation, there’s the capability for blowing fiber, facilitating telecommunications utilities like FTTH, FTTB, FTTCS, and FTTT.

- Electric Vehicle Charging Installations: In urban projects, tunnels might specifically cater to EV charging station infrastructure or other smart city utilities.

- Manhole Wreckout Installation: Manholes are positioned to provide regular maintenance access in the future.

- Collaboration & Synergy:

-

- Engaging Subcontractors: For tasks that require specialized knowledge, subcontractors are often involved to ensure quality.

- Joint Trenching: On occasion, the tunnels might incorporate joint trench solutions for multiple utilities running side by side.

- Emergency and Safety Protocols:

-

- Emergency Response & Rescue: During boring, mechanisms for rapid response to emergencies, such as breaches or mechanical failures, are in place.

- Safety Standards: Pro measures ensure safety, especially in areas near railroads or critical infrastructure.

- Post-Boring Activities:

-

- Restoration & Rehabilitation: Upon completion, the landscape is restored to its original state, minimizing environmental impact.

- OSP Management: The utilities installed, being part of the Outside Plant, are maintained and managed long-term.

- Future Considerations:

-

- Upgrades & Extensions: The created tunnel can be extended or upgraded based on future requirements or developments in technology.

Tunnel boring, by its very design, is a testament to engineering marvels, enabling expansive underground infrastructure with minimal disruption to the surface. Through strategic planning, collaboration, and employing state-of-the-art machinery, it ensures the seamless establishment of tunnels serving various utilities and purposes.