Tunnel Construction: A Comprehensive Guide on Processes and Services

Tunnel construction is a sophisticated procedure, often necessitated for infrastructure projects, transport routes, and utility installations beneath obstacles such as mountains, water bodies, or urban areas. Utilizing the given terms, let’s delve into the intricacies of tunnel construction:

- Project Initiation:

- Engagement with Professionals: Local LLCs or larger corporations might seek the expertise of tunnel construction companies. Pros in the field provide consultation to determine feasibility and approach.

- Site Evaluation: Experts assess the construction site to determine its boreability, especially in areas with hard rock or challenging geological conditions.

- Planning & Design:

-

- Horizontal Analysis: Given that tunneling typically concerns horizontal excavation, detailed plans ensure the correct depth and direction.

- Government & Military Approvals: Necessary permissions are procured, particularly when tunnels might intersect with military zones, highways, or interstates.

- Excavation & Boring:

-

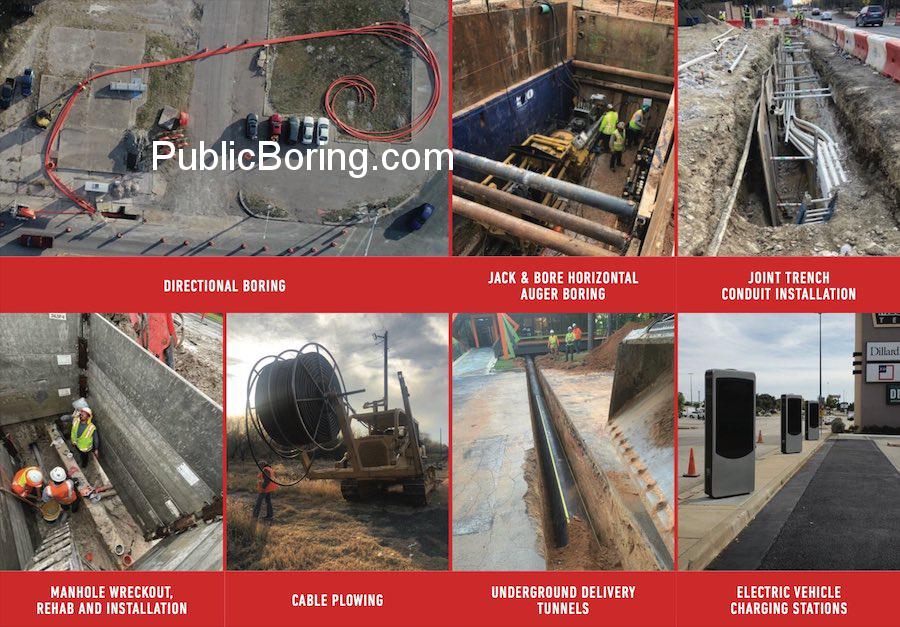

- Choosing the Method: Depending on the site’s geology, either conventional excavation methods like hand digging and hand trenching are used, or advanced techniques like tunnel boring machines or the jack and bore method might be employed.

- Managing Hard Rock: In regions with hard rock, specialized techniques or equipment, potentially including auger tools, might be used to enhance efficiency.

- Utility & Infrastructure Integration:

-

- Ductbank Work: As the tunnel is constructed, there might be concurrent ductbank installation for protective casing of utilities.

- Utility Installation: Electrical conduits, fiber boring for telecommunications like FTTH or FTTB, and even infrastructure for electric vehicle charging stations can be integrated.

- Water & Sewer Management: Depending on the tunnel’s purpose, provisions for sewer lines or water management might be added.

- Collaborative Work:

-

- Subcontractor Engagement: For tasks that necessitate specialized expertise, subcontractors can be engaged, ensuring the best results.

- Joint Trench Solutions: In scenarios where multiple utilities are to be housed, joint trenching provides an efficient and consolidated solution.

- Safety & Emergency Protocols:

-

- Emergency Provisions: Throughout construction, mechanisms are in place for emergencies, from potential water influxes to equipment malfunctions.

- Safety First: Proactive measures are instated, especially when working near areas like railroads, to ensure the safety of workers and the public.

- Finishing & Rehabilitation:

-

- Manhole and Access Points: Manholes are strategically placed, offering maintenance and access points in the future.

- Rehabilitation & Restoration: Post-construction, the disturbed landscape undergoes rehabilitation to return it to its natural or intended state.

- Post-Construction Services:

-

- Maintenance & Upkeep: Companies offer maintenance services, ensuring the tunnel and its utilities, like those in the Outside Plant (OSP), remain functional.

- Upgrades & Extensions: As technology advances or needs change, tunnels can be updated or extended.

Tunnel construction is more than just creating an underground passage; it’s about facilitating transportation, utility delivery, and other essential services in a manner that’s safe, efficient, and minimally disruptive to the environment and community. Through meticulous planning, state-of-the-art equipment, and skilled execution, tunnels serve as lifelines in modern infrastructure.