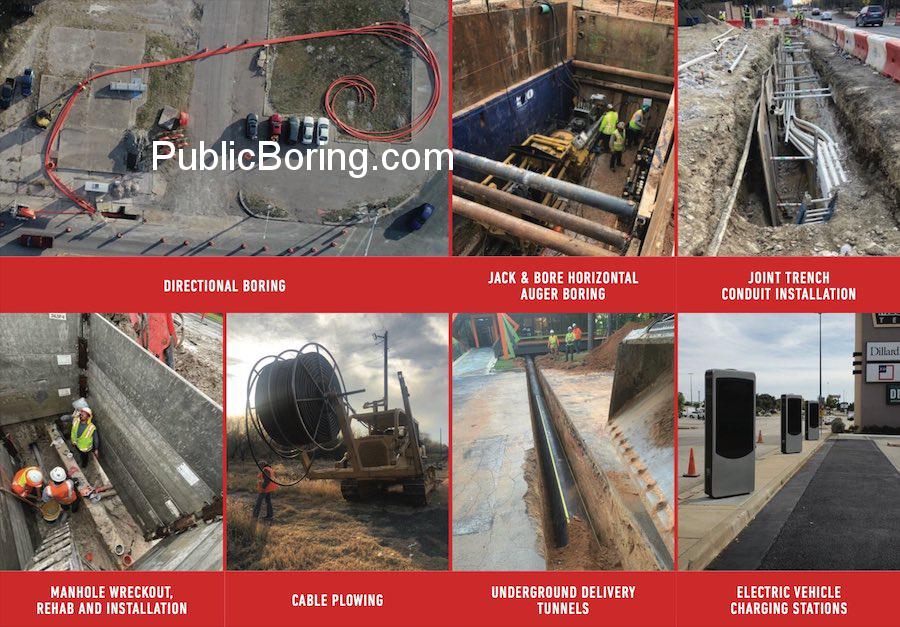

Tunnel Digging: A Detailed Overview of Processes and Services

The art of tunnel digging is a multidimensional process, marrying traditional methods with modern technology to connect places, transport goods, and facilitate utilities. Below is a detailed description of the services and steps involved in tunnel digging using the provided terms:

- Planning & Consultation:

- Engaging the Right Company: Many construction companies, from local LLCs to larger corporations, offer tunnel digging services. The best companies are sought after for their expertise and experience in tunneling.

- Assessment of Terrain: Before commencing, it’s vital to check the boreability of the area. Areas with hard rock may require different tools and techniques than more boreable terrains.

- Government & Regulatory Approval: Especially when dealing with public utilities or if the tunnel intersects highways, interstates, or military zones, permissions are imperative.

- Initial Excavation:

-

- Hand Digging & Hand Trenching: In certain situations, especially where precision is key or where machinery access is limited, conventional hand methods might be employed.

- Utilizing Equipment: For larger projects or challenging terrains, machinery like augers and cable plows are used.

- Tunnel Boring:

-

- Conventional Boring: This involves manually or mechanically digging tunnels, especially in softer terrains.

- Trenchless Boring & Jack and Bore: These are modern techniques, often used to minimize surface disruption, especially beneficial for urban areas or places with existing infrastructure.

- Managing Hard Terrains: In regions where hard rock exists, special equipment or slick bores are used for smoother operations.

- Integration of Utilities & Infrastructure:

-

- Installing Ductbanks: To ensure that the utilities within the tunnel are organized and protected, ductbanks are installed. This ductbank work includes placement of electrical, fiber, and other conduits.

- Utility Services: Conduits for electrical services, fiber boring for advanced communication setups like FTTH, and provisions for EV charger stations might be integrated depending on the tunnel’s purpose.

- Collaborative Aspects:

-

- Joint Trenching: If the tunnel serves multiple utilities, joint trenching provides a consolidated solution, saving space and ensuring efficiency.

- Subcontractors: Specialized tasks, such as the installation of certain utilities, might be outsourced to expert subcontractors to ensure the best results.

- Safety Measures & Protocols:

-

- Emergency Preparations: With the inherent risks of tunnel digging, especially when operating near railroads or busy roads, emergency protocols and rescue services are on standby.

- Water & Slurry Management: In cases of wet conditions or water ingress, measures are in place to deal with the slurry and prevent flooding.

- Finalization & Surface Rehabilitation:

-

- Manhole Installation & Rehabilitation: Manholes are strategically constructed for future access and maintenance. Any wreckouts are addressed, and rehabilitation ensures functionality.

- Restoration: Post-digging, the disturbed landscape and surface areas undergo restoration to minimize environmental impact.

- Post-Digging Services:

-

- Maintenance & Upgrades: Tunnel service providers often offer periodic inspections, maintenance, and upgrade services to ensure longevity and functionality.

Tunnel digging, in essence, is not merely about creating an underground passage. It represents a fusion of engineering prowess, safety measures, environmental consciousness, and meticulous planning. Through the collaboration of pros in the industry and the integration of both conventional and advanced techniques, tunnels provide solutions for modern infrastructural challenges.