Utility Boring: A Detailed Insight into Procedures and Services

Utility boring, also known as horizontal directional drilling, is a trenchless method used to install utilities underground. This method is preferable due to its minimal disruption to the surface, particularly in urban areas or sensitive terrains. Here’s a comprehensive overview of the steps and services provided by utility boring specialists using the provided terms:

- Initial Engagement and Assessment:

- Expert Consultation: Clients seeking the best utility boring services often approach reputed companies or LLCs with experts in the field.

- Site Evaluation: Before starting, it’s vital to assess the ground. Is it boreable? What are the challenges presented by hard rock or existing infrastructure?

- Site Preparation:

-

- Construction Site Development: This involves preparing the site to accommodate equipment, ensuring access, and establishing safety measures.

- Regulatory Compliances: Especially when working near highways, interstates, railroads, or military zones, it’s imperative to secure permissions from the government or local bodies.

- Utility Boring Process:

-

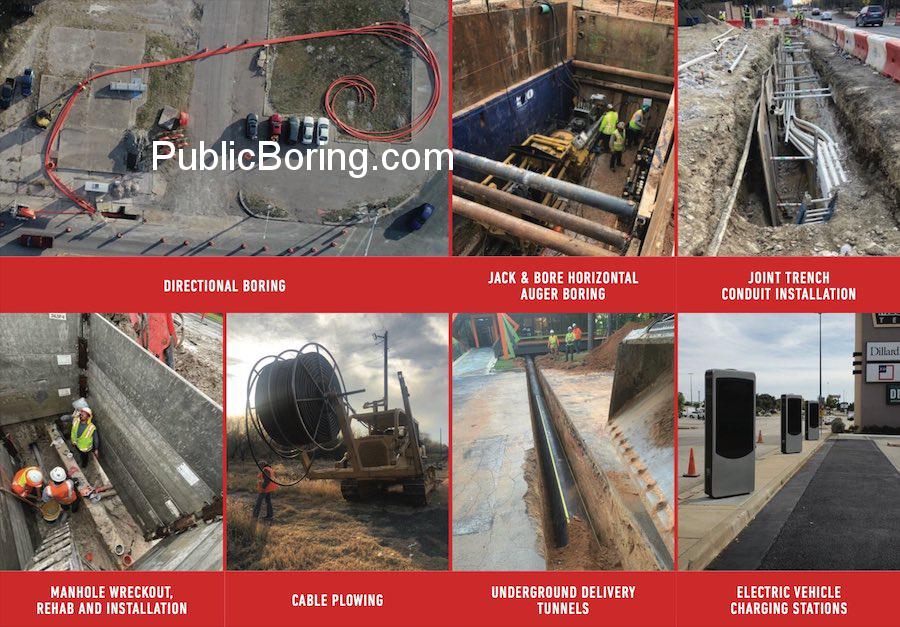

- Trenchless Techniques: Utility boring is primarily a trenchless method. This can include horizontal boring or the specialized jack and bore technique.

- Fiber Boring: For telecommunications or FTTH (Fiber to the Home) services, utility boring specifically tailored for fiber optic installations is employed.

- Auger Boring: Using an auger, this method is often chosen for bores in stable soil conditions.

- Utility Laying & Integration:

-

- Conduit Installation: Conduits are essential to protect and house the utilities being laid underground.

- Ductbank Work: The ductbank installation process organizes multiple utilities efficiently, especially crucial for electrical or fiber services.

- Cable Plowing: In certain circumstances, the cable plow method might be used in tandem with utility boring to lay cables.

- Collaborations and Partnerships:

-

- Working with Subcontractors: Utility boring projects might require specialized skills, leading companies to collaborate with subcontractors for tasks like EV charger installations or solar farm connections.

- Co-op Engagements: Utility boring firms often work in co-op arrangements, especially when tackling large-scale infrastructure projects for smart cities or OSP (Outside Plant) operations.

- Safety and Emergency Protocols:

-

- Water and Slurry Management: In wet conditions, managing water ingress or slurry is essential to maintain the bore’s integrity.

- Emergency Measures: Given the subterranean nature of the work, utility boring contractors must have rescue and emergency protocols in place, especially in proximity to busy roads or railroads.

- Post-Boring Activities:

-

- Landscape Rehabilitation: Post the boring activity, it’s crucial to restore the landscape, ensuring minimal environmental or aesthetic impact.

- Manhole Installation & Management: Manholes facilitate access for future maintenance. The process involves installation, rehabilitation, and strategic placement.

- Testing & Activation: After utilities are installed, they’re tested for functionality before activation.

- Maintenance and Upgrades:

-

- Ongoing Support: Utility boring doesn’t end with installation. Companies offer ongoing support to ensure the utility’s longevity and efficiency.

- Expanding Services: As infrastructure needs evolve, utility boring services adapt, whether it’s extending FTTCs (Fiber to the Curb) or integrating newer utilities.

Utility boring stands as a testament to technological evolution in underground construction, ensuring that communities and cities enjoy seamless utility delivery with minimal surface disruption. The meticulous process, managed by pros in the industry, underscores the significance of strategic planning, collaboration, and adaptability.