Utility Directional Drilling: A Comprehensive Overview

Utility Directional Drilling (often referred to as Horizontal Directional Drilling or HDD) is a specialized trenchless construction method utilized for the installation of underground pipes, conduits, and cables. This method reduces environmental impact, making it ideal for areas where traditional excavation is either impractical or too disruptive. Here’s an extensive breakdown using the provided terms:

- Initial Consultation and Planning:

- Company Expertise: Engaging with reputable companies or corporations is vital. Whether it’s a local LLC or a larger Corp., it’s essential to ensure that they have the required expertise.

- Site Survey: Experts evaluate the ground conditions. Is it boreable? Are there hard rock challenges? Understanding these factors is crucial to decide on the best drilling method.

- Site Development & Preparation:

-

- Construction Site Development: The area is prepared for equipment setup, ensuring accessibility and establishing necessary safety protocols.

- Regulatory Approvals: Especially for projects near highways, railroads, military areas, or interstates, permissions from the government or local authorities are paramount.

- Directional Drilling Process:

-

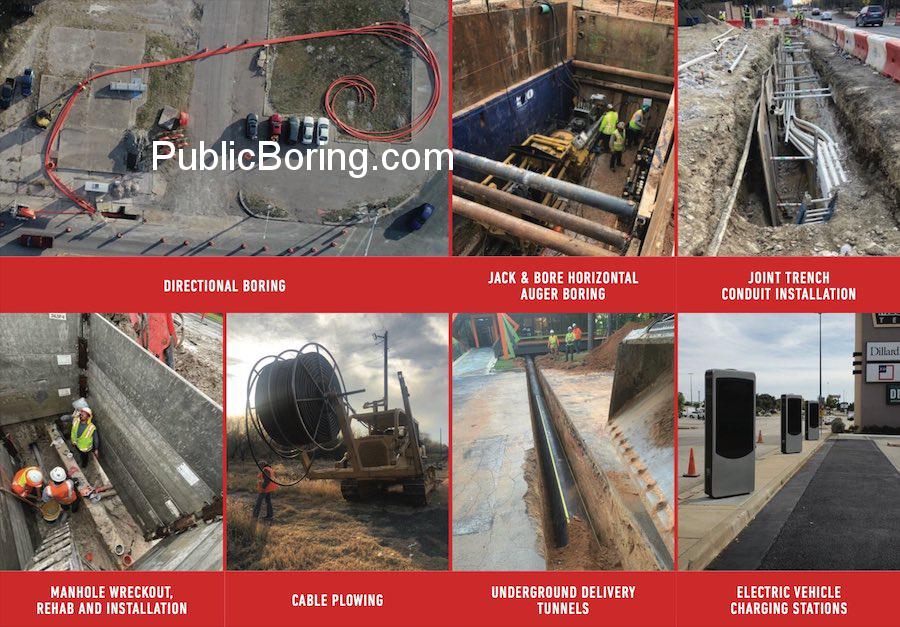

- Auger Drilling: In cases where the soil is stable, auger drilling might be utilized.

- Fiber Boring: For the installation of fiber-optic cables – whether it’s FTTH (Fiber to the Home), FTTB (Fiber to the Building), or other types.

- Conduit and Ductbank Installation: Conduits protect the installed utilities. The ductbank installation then organizes these conduits, especially important for electrical or telecommunication services.

- Horizontal Drilling: As the name implies, utility directional drilling primarily employs a horizontal approach, allowing for the installation of utilities without disturbing the surface above.

- Collaborative Work & Partnerships:

-

- Joint Trenching: In projects where multiple utilities need installation, joint trenching might be employed, ensuring efficient use of space.

- Co-op Engagements: Drilling specialists often collaborate in co-op settings, especially for large-scale infrastructure tasks or OSP (Outside Plant) operations.

- Subcontractor Partnerships: For specialized tasks, such as electric vehicle charging station setups or connections to solar or wind farms, subcontractors might be engaged.

- Safety, Rescue, and Contingencies:

-

- Emergency Protocols: Given the risks associated with subterranean work, established rescue and emergency measures are vital, especially when working close to active roads or railroads.

- Slurry and Wet Conditions: Managing water or slurry is key, ensuring the stability of the bore.

- Finishing and Post-Drilling Activities:

-

- Manhole Management: Post-drilling, manholes are strategically placed for future maintenance and access, involving careful installation, rehabilitation, and placement.

- Landscape Rehabilitation: The final step involves restoring the site to its original state or better, ensuring minimal long-term environmental or aesthetic impact.

- Testing & Quality Checks: Once utilities are in place, rigorous tests ensure functionality and safety.

- Future-proofing and Expansions:

-

- Small Cell & Smart City Integration: As urban areas evolve, the infrastructure installed via utility directional drilling might be upgraded or expanded, catering to smart cities or small cell installations.

- Ongoing Support & Maintenance: Pro firms offer continued support to address any issues and ensure the longevity of the installed utilities.

Utility Directional Drilling offers a balanced blend of technical prowess and environmental consciousness. By leveraging the pros in the industry and adapting to technological advances, it promises efficient underground utility delivery for contemporary and future needs.